PLAGATE System Hot Runner Forming Device

Temperature control box

PN-C

seriesPN-CM series

gate timing controller

High-precision temperature control by micro multi-purpose computer

Automatically control the temperature of nozzle and runner plate to maintain optimal molding conditions.

In addition, the PID control of the micro multi-purpose computer can improve the control accuracy and realize the self-diagnosis function.

Features of PLAGATE Controllers

1. Adopt PID control to suppress temperature overshoot

- Feedback control is carried out through a high-precision micro multi-purpose computer to improve the accuracy of temperature control. At the same time, the temperature overshoot or undershoot can be prevented by PID control.

2. Independent circuit control, detachable unit structure

- Each circuit is constituted independently, the temperature setting of each area is intuitive and easy to understand, and the operation is simple. In addition, each circuit adopts a unit structure, which greatly improves the maintainability.

3. The circuit protection of each point adopts the safety design of the leakage circuit breaker

- The circuit protection of each point adopts the safety design of the leakage circuit breaker

4. Protect the heater by soft start

- Prevents sudden current flow after the start of temperature control, which can greatly reduce the burden on the heater

5. PN-CM series is a touch screen style, which can be combined in various ways

- PN-CM series can be operated by touch screen.

- The maximum number of communication channels can be set to 140 channels.

- Gate timing control options can be built in.

- The number of communication channels of the PN-C model can be selected from 2ch, 4ch, 6ch, and 8ch

- and then used in combination with the timing controller,

- It can effectively control the needle valve gate of the pneumatic nozzle.

6. Other rich functions

- Responsiveness is improved by double differentiation (PIDD),

- To suppress temperature fluctuations caused by external disturbances.

- Even if loads and environmental conditions change,

- An automatic adjustment function for temperature control is also possible under optimal conditions.

- Safety design that detects the abnormality of each circuit of heater and sensor and accurately alarms.

- The mold and controller can be quickly disassembled and assembled with the connecting line, and the operation is simple

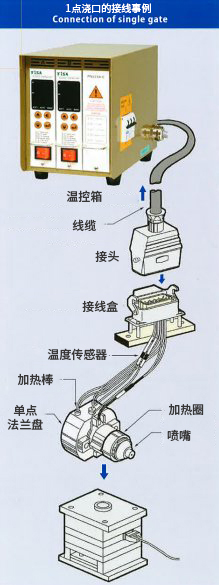

EXAMPLE OF CONNECTION Example of wiring

DownLoad various data downloads

Regarding molding problems, please feel free to inquire at any time

Hot runner technical consultation

Download

consult

contact us

If you have any questions, please click here to consult and look forward to your contact.

Service Hotline

0512-67086298