PLAGATE System hot runner forming device

Spring Type Nozzle

AH2/AH4

The gate closing method that other companies do not have.

FISA's patented gate closing method can completely block the reverse flow problem from the mold cavity

Features of the AH series

- POINT3

- Versatile gate settings

- POINT7

- Interchangeable with NH type

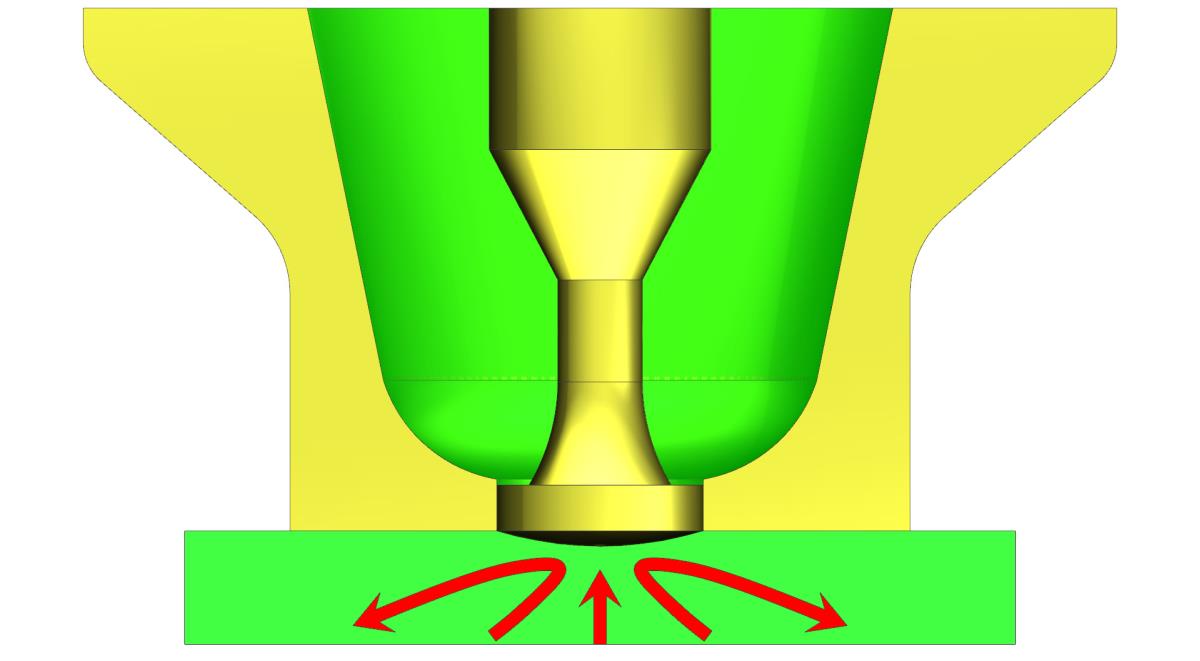

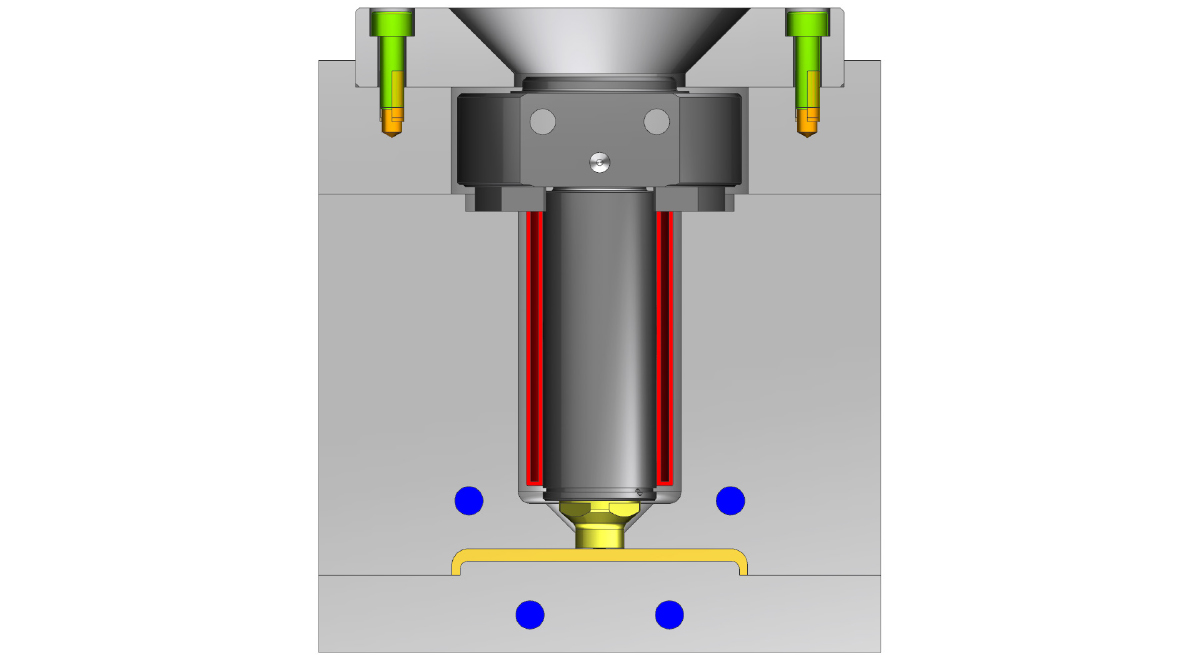

1. A switching system that uses resin pressure as the driving force

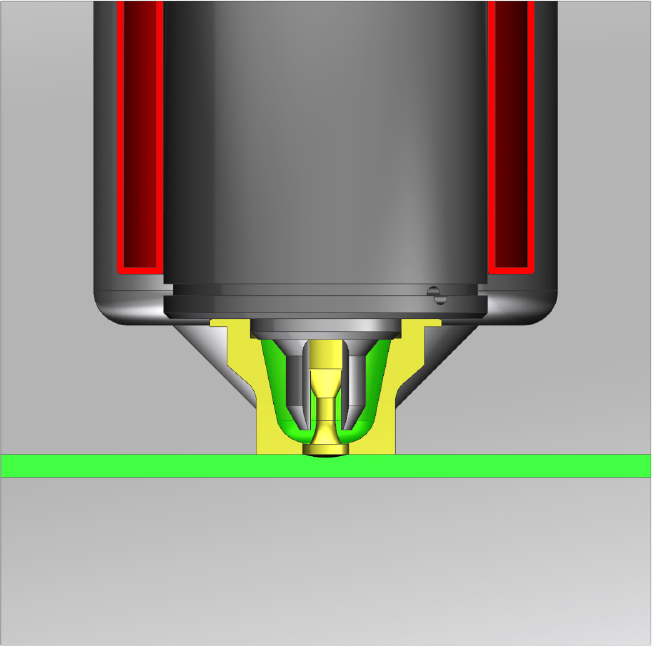

- When there is no resin pressure, the spring elasticity keeps the needle valve closed

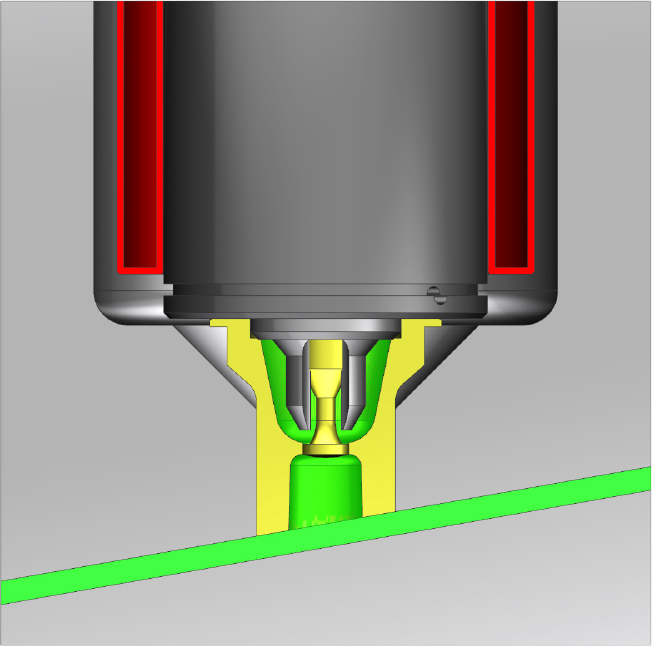

- When subjected to injection pressure, the injection pressure causes the needle valve to advance and the nozzle opening is opened

- When the mold cavity is filled with plastic, the injection pressure drops, the elasticity of the spring automatically pushes the valve pin back, and the nozzle port is closed

2. Prevent resin counterflow

- The valve pin is receded to close the gate completely

- Therefore, there will be no cavity resin counterflow problem

- In particular, gas jet forming

- and injection molding compression molding can be the most effective

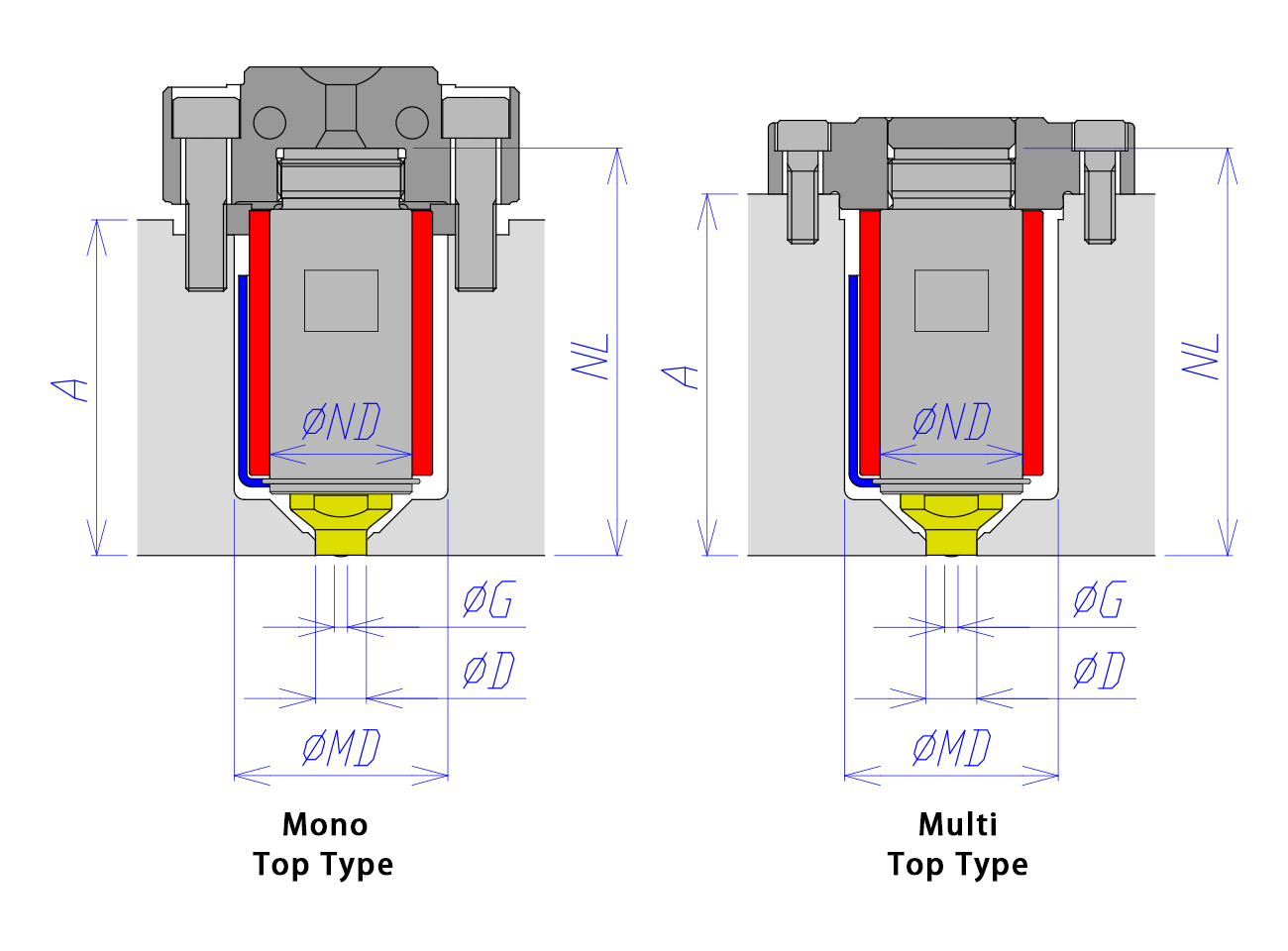

3. Gate settings available for selection

- Form a round head style, form a long nozzle head pattern with a material handle.

The above 2 types are available

There is a head style

There is a head style Long nozzle head specifications

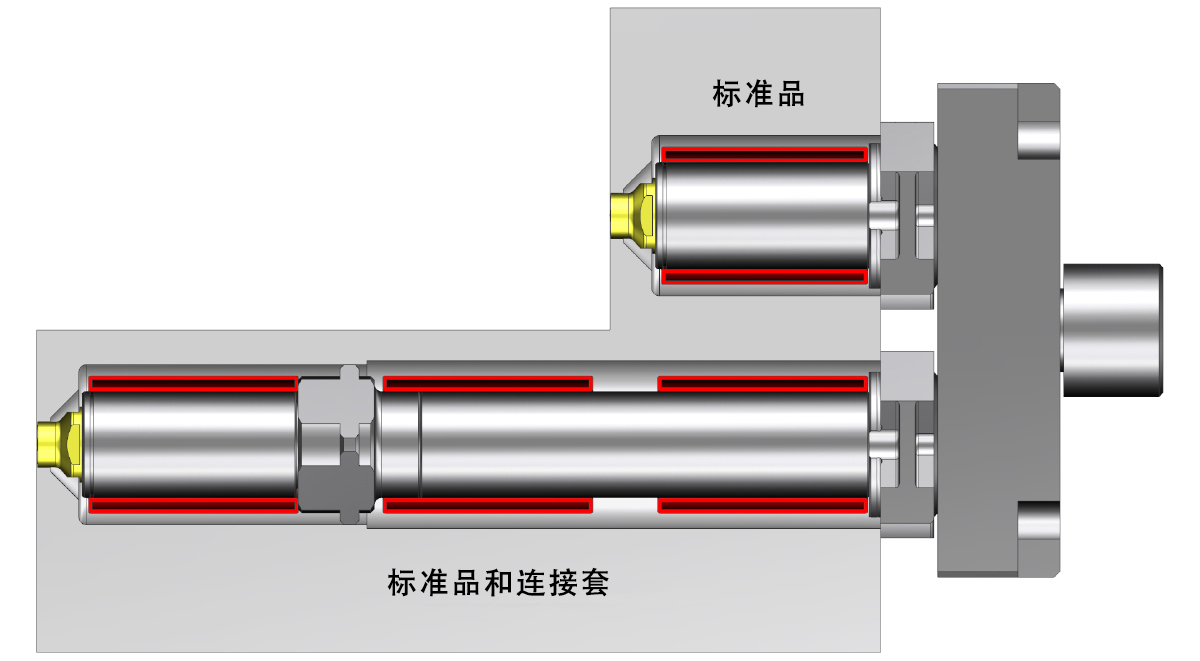

Long nozzle head specifications4. Extend the connection sleeve

- If a long nozzle above the standard is required, it can be responded by using a connection sleeve.

The length can be made according to the mold size.

Please consult our company for details

5. The setting of the mold center point is simple

- Because there is no external drive such as a cylinder, the gate setting at the center point of the mold is easy

6. Basically the parts are in the library, and the maintenance is simple and convenient

- Basically, the parts are in the library

, and the domestic products in China are maintained, which can be corresponded immediately

7. Interchangeable with NH type

- The installation of the NH type nozzle with head, long nozzle head and mold is fully interchangeable.

Nozzle replacement is required without modification of the mold.

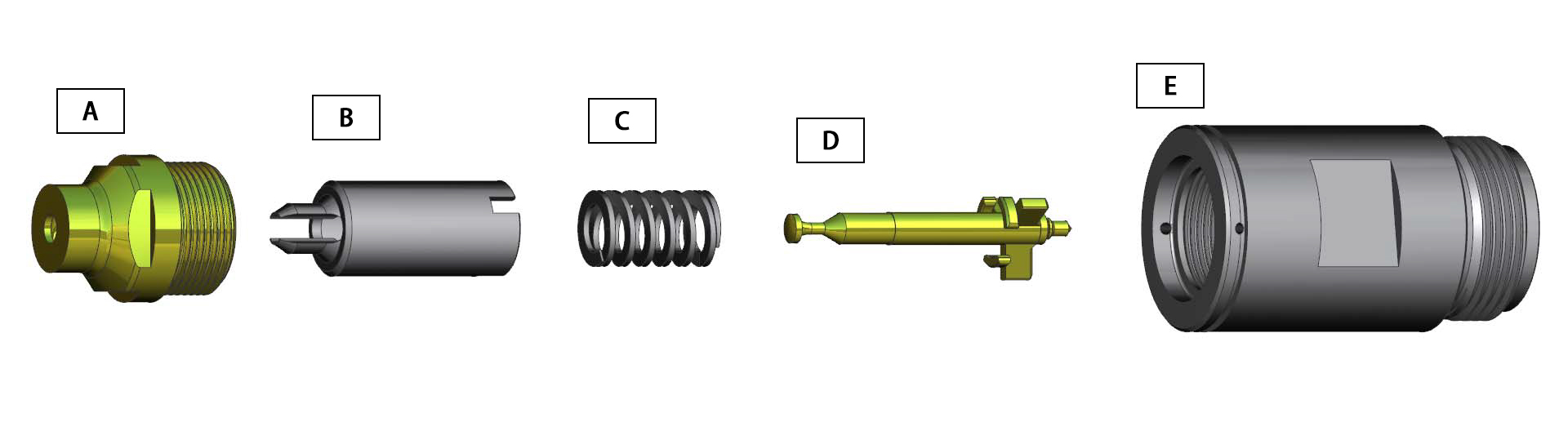

Structure Chart Composition Diagram

A = Nozzle head (with head)

C = Spring

E = nozzle body

B = Thermal cover

D = needle valve

Standard spec sheet

Download various data downloads

Regarding molding problems, please feel free to inquire at any time

Hot runner technical consultation

Download

consult

contact us

If you have any questions, please click here to consult and look forward to your contact.

Service Hotline

0512-67086298