PLAGATE System Needle Valve Nozzle

Needle valve nozzle

NR2/NR3/NR4/NR5

NRS30/NRS40/NRS50

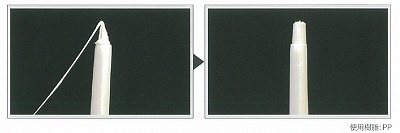

Completely prevent wire drawing and drooling of injection molding machines

Model NR is a needle valve nozzle used in thermoplastic molding machines and is a reliable needle valve gate system. It is widely used by various molding machine manufacturers.

Features of the NR series

- POINT2

- prevent wire drawing

- POINT3

- prevent salivation

- POINT6

- Built-in strong spring

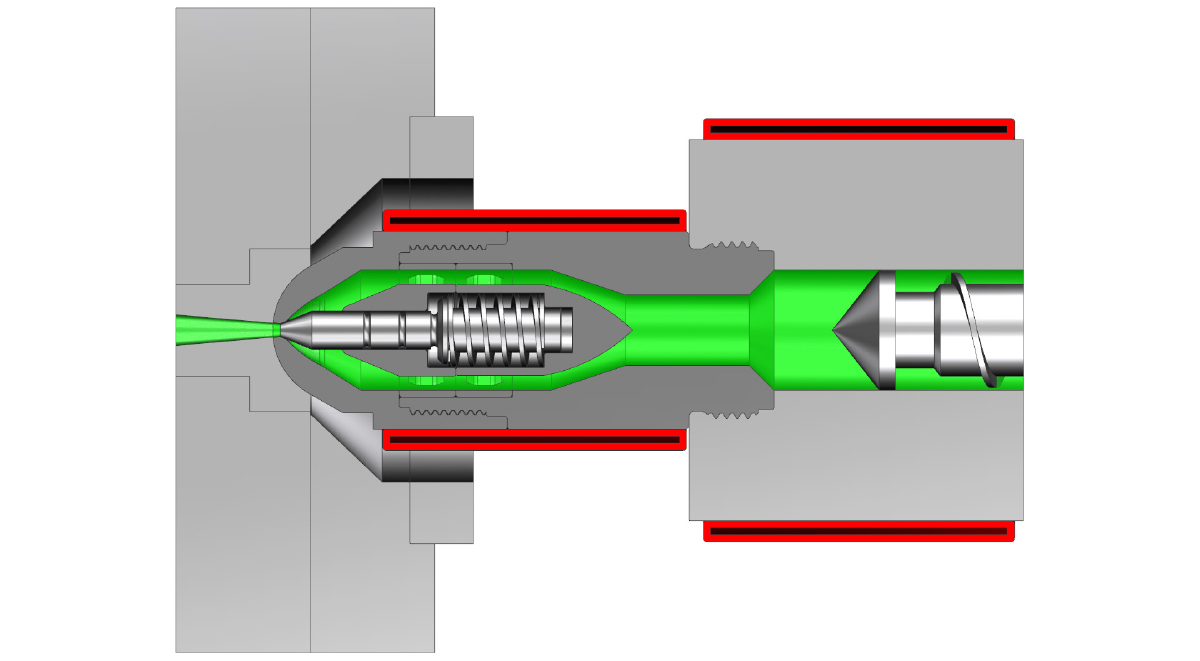

1. Prevent backflow from the mold cavity

- The built-in strong spring allows the valve pin to completely close the gate without causing backflow of resin

2. Prevent wire drawing problems

- In particular, it is very effective for resin molding with good fluidity.

3. Prevent salivation problems

- The gate is completely closed, reducing the generation of cold material and improving the quality of molded products.

4. Improve instant shot rate

- The resin in the nozzle is injected under pressure to increase the filling speed.

5. Structure without stagnant space

- The resin flow path in the nozzle is streamlined and has no residual resin to prevent burning problems.

6. Built-in strong spring

- The use of super alloys improves durability through advanced heat treatment technology.

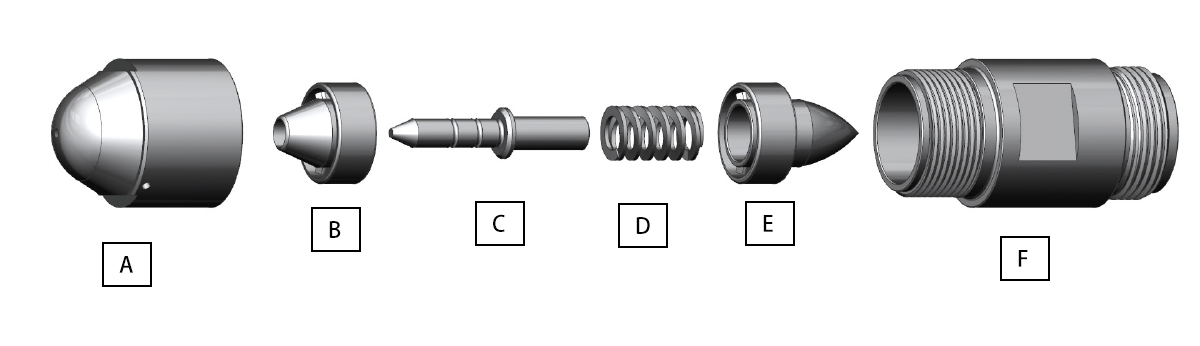

Structure Chart

A=Nozzle head

C=Needle valve

E = rear shunt shuttle

B = Front Shunt Shuttle

D=spring

F=Nozzle body

DownLoad various data downloads

Regarding molding problems, please feel free to inquire at any time

Hot runner technical consultation

Download

consult

contact us

If you have any questions, please click here to consult and look forward to your contact.

Service Hotline

0512-67086298