A burr

-free .

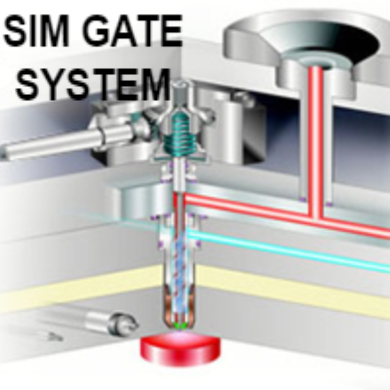

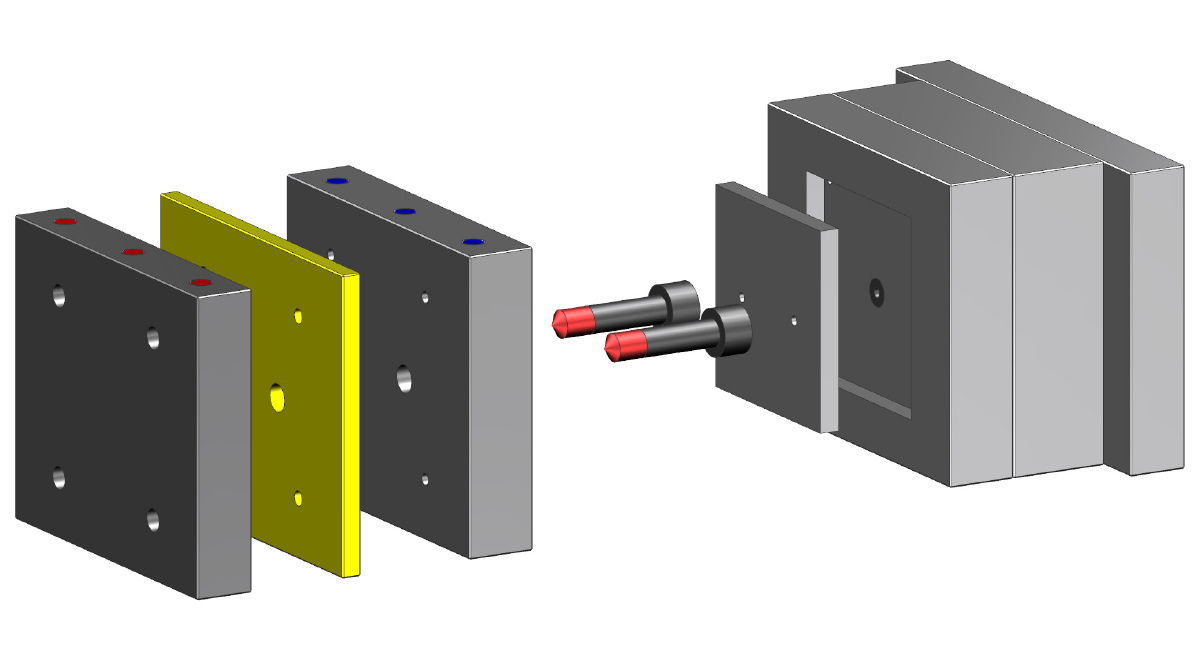

It is assembled into an injection mold of liquid silicone, and the gate can be completely closed by FISA's unique needle valve method. Best for high-speed, vertical, insert molding.

Features of LIM Molding Units

- POINT1

- 2 gate switch modes

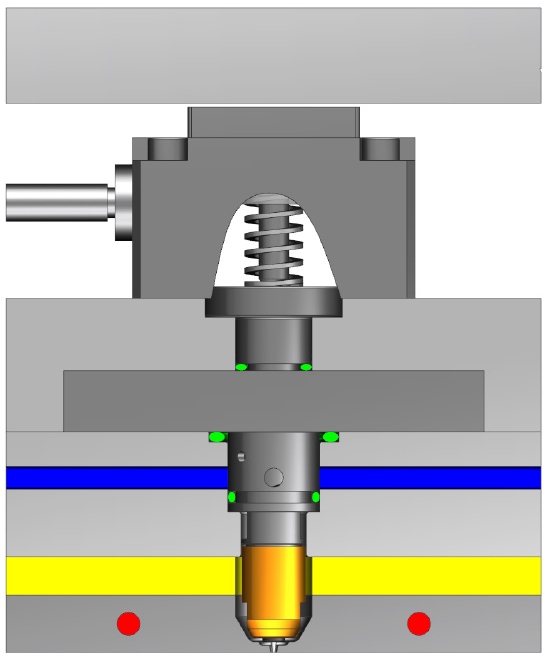

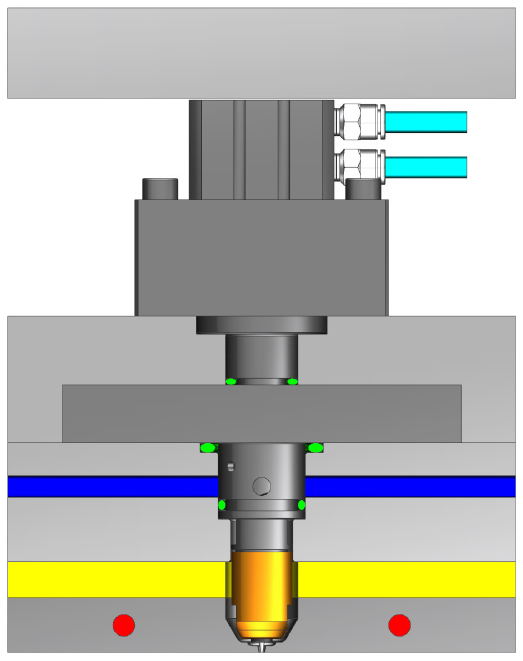

1. Two gate switch modes

- The "spring type" of the gate switch is controlled by injection pressure and spring force; the "pneumatic type" of each gate switch is freely adjusted by the cylinder.

- There are 2 options above

spring

spring pneumatic

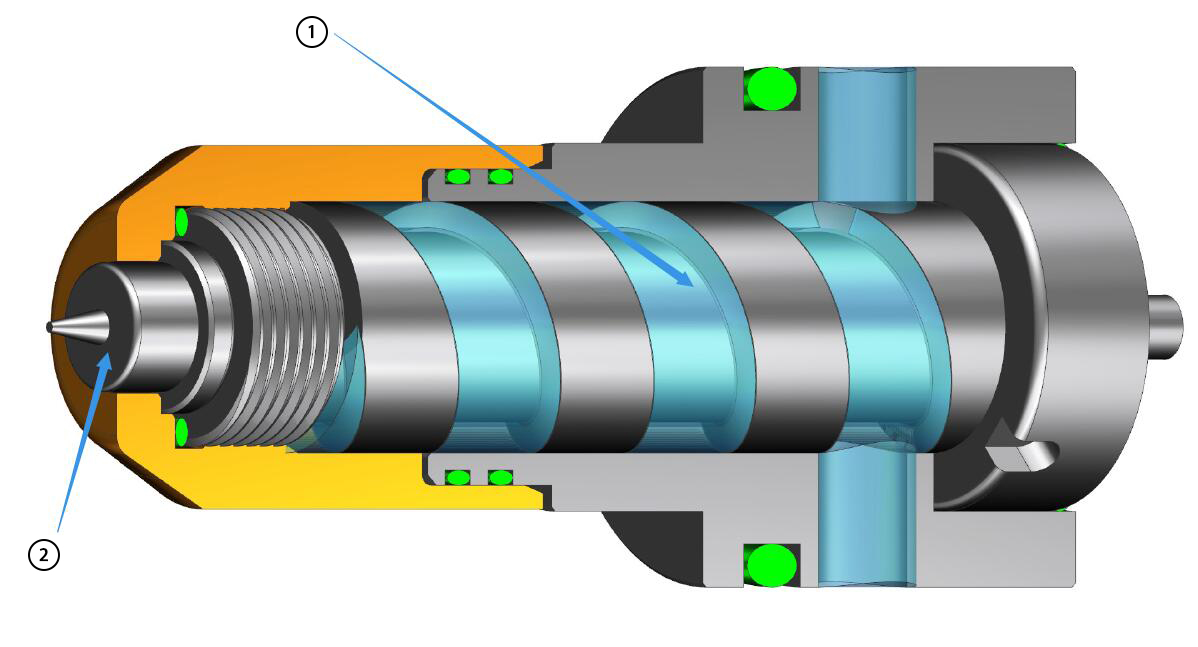

pneumatic- ■ Spring-type action principle

- ・The gate is closed by the spring force of the needle valve

- ・When the injection pressure is applied, the injection pressure causes the needle valve to retreat and the gate is opened

- ・When the mold cavity is filled, the pressure in the nozzle drops, the spring force moves the needle valve forward, and the gate is completely closed

2. Prevent vulcanization inside the nozzle

- ① The spiral circulating cooling water inside the nozzle can prevent the vulcanization of the material

- ② The front end of the nozzle uses a special alloy to effectively block the heat conduction from the mold to the nozzle.

3. Structure with excellent maintainability

- The design with excellent maintainability while maintaining formability enables smooth nozzle assembly and disassembly.

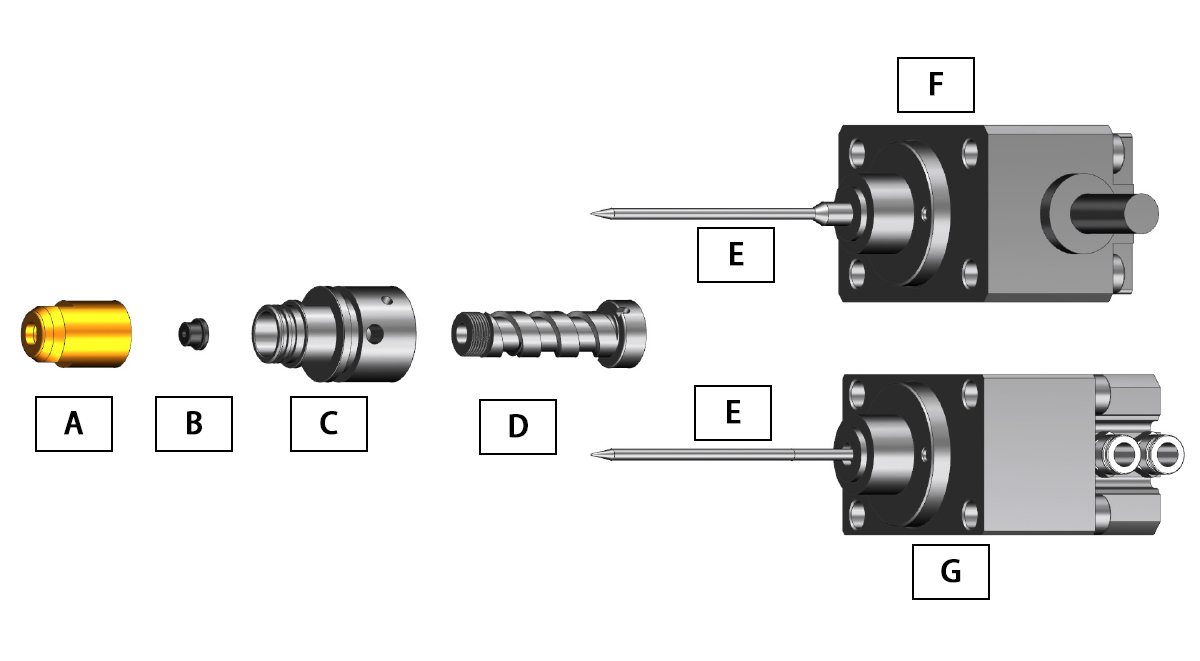

Structure Chart

A=Nozzle head

C=Nozzle body

E = valve needle

G=Cylinder

B = head end

D = hose

F = cylinder

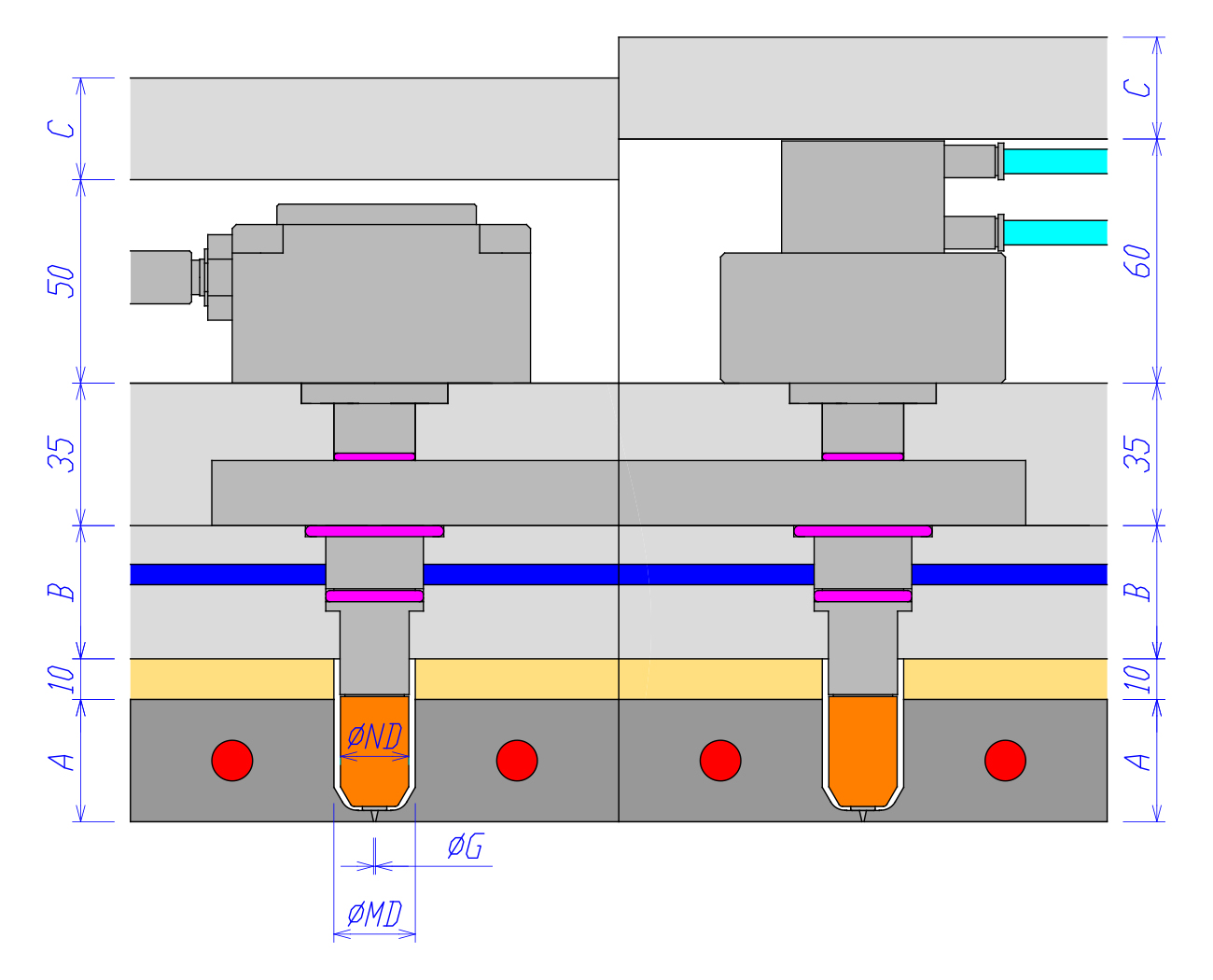

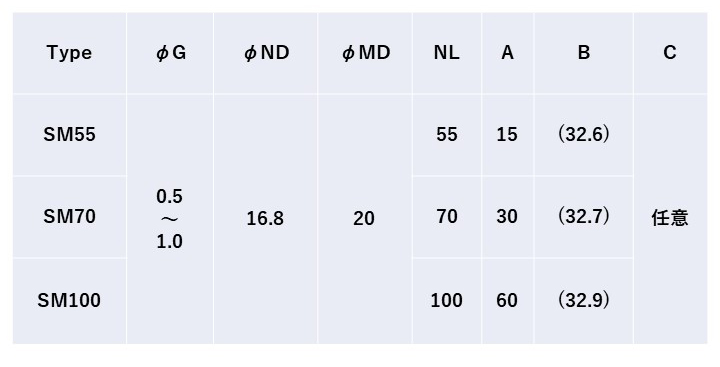

Standard Specification Sheet

※ Minimum gate spacing = 45㎜

DownLoad various data downloads

Regarding molding problems, please feel free to inquire at any time

Hot runner technical consultation

Download

consult

contact us

If you have any questions, please click here to consult and look forward to your contact.

Service Hotline

0512-67086298