A large area of 700mm wide area remover, with a fan with large air volume, can remove electricity at high speed even at a long distance.

It can correspond to large-area fan-type eliminator, with ion plate, high-precision ion balance and high-speed static eliminator. Maintenance frequency is reduced. The applicable area for static elimination is 2.5 times that of the standard type (FD-F120D). Most suitable for static elimination of large products.

Features of FD-F360

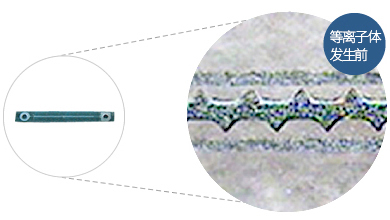

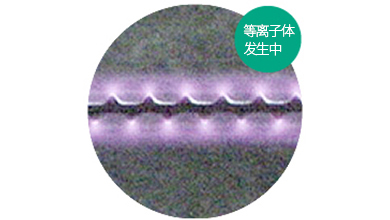

1. Surface discharge produces low ions

The ION BLADE is composed of a dielectric and a sawtooth-shaped microelectrode formed on its surface. Since it has a high density of plasma generating points, it can efficiently and uniformly generate high-concentration ions over the entire surface of the element.

Electrode part enlarged view

The state of the plasma

In conventional electrostatic precipitators with needle electrodes (corona discharge method), the electrolysis at the tip of the needle emits ions from concentrated "points", while ION BLADE emits "surface" ions from the entire surface of the element due to its flat shape.

conventional electrodes

The electric field is concentrated at the front and ions are generated from the point

There is dust attached to the front end, and performance degradation is a major problem

ION BLADE

The electric field is uniform, and ions are generated in a planar shape.

Due to the surface shape, it is difficult for dust to adhere to the front end

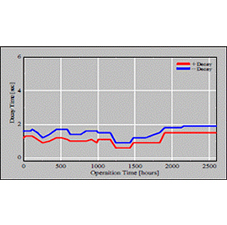

2. Reduced maintenance times & reduced operating costs

- Compared with the needle-type electrode used in the conventional eliminator (corona discharge method), this product can generate ions under low voltage conditions and reduce dust adhesion caused by the electric field.

3. Simple to run

- The electrode is a simple plane structure. Open the front guard to clean the electrode, fan, etc., and the operation is simple.

※1 Hold the front panel, turn it about 30 degrees to the left, and then pull toward you.

※2 Carefully remove the connection terminals of the inner and outer FD rings.

※3 Wipe the dirty part with a cotton swab, cloth, etc. soaked in alcohol.

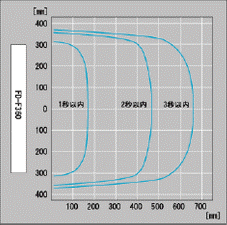

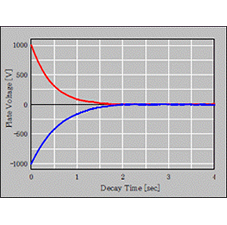

Neutralization Area Discharge Time Neutralization Area Discharge Time

Static elimination area (representative example)

Static elimination time (from the front 300mm, representative example)

Time change (no electrode cleaning required, representative example)

Measurement conditions: When the air volume is the largest, use a 150×150mm (20pF) charging board monitor to measure the static elimination time from ±1000V→±100V; the static elimination time and the time change are measured from 300mm in front of the center of the air outlet .

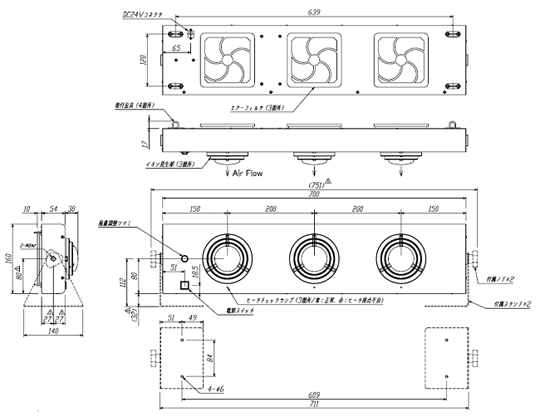

External Dimensions

DownLoad various data downloads

Regarding molding problems, please feel free to inquire at any time

Hot runner technical consultation

Download

consult

contact us

If you have any questions, please click here to consult and look forward to your contact.

Service Hotline

0512-67086298